Steel & non-ferrous

From the Eifel tower to oil platforms, paper clips, artificial hips, cars, couplings and much more. It can be said that steel and non-ferrous materials are literally used as a basic material everywhere.

The production and transformation of steel and non-ferrous materials is changing these days - it is becoming more flexible while at the same time it needs to be more efficient and more environmentally friendly. For staff at the steel mills this means making the production process more technically and economically competitive in the long term. Gear couplings with high torque and high misalignment capacity are used throughout the production drive lines of steel, from casting, slab, and billet to finished thin sheet, bars or profiles. The precision gearing of ESCOGEAR couplings improves the quality finish of the steel product.

ESCOGEAR and ESCODISC couplings contribute to the reliable production of the highest quality steel, as expected by customers. Using ESCOGEAR and ESCODISC solutions with lifetimes as long as 20+ years reduces unplanned downtime and consequently unnecessary costs.

- ESCOGEAR special gear spindles are installed on continuous casting rolling mills and cold rolling or slitting installations

- Rolling mill conveyors, Main motors, Steel converters, Slitting lines, Tensioning drives, Coilers, Painting and annealing lines are ESCOGEAR regular and familiar applications

C & C-M - series

Torque up to 348,000 Nm+

Bore up to 290 mm+

DMUCC - series

Torque up to 29,600 Nm

Bore up to 350 mm

DISC COUPLINGS - DPU series

Torque up to 23,100 Nm

Bore up to 220 mm

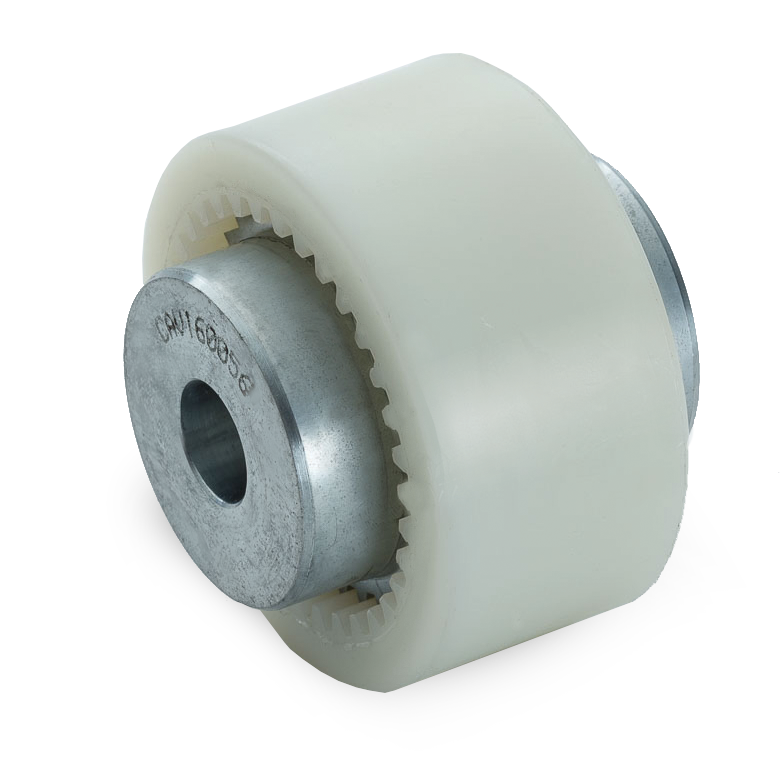

Escoflex A - series

Torque up to 2,850 Nm

Bore up to 100 mm

N - series

Torque up to 2000 Nm

Bore up to 85 mm