Gear couplings - F Series

Characteristics of the ESCOGEAR F series couplings

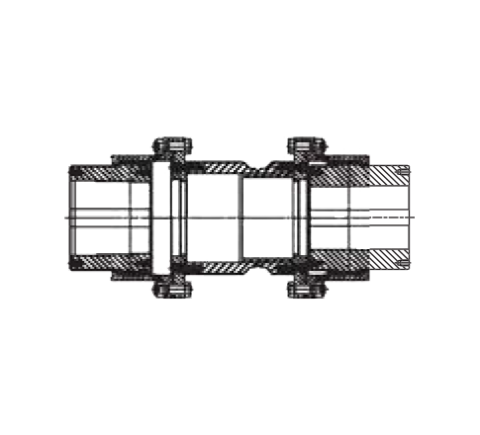

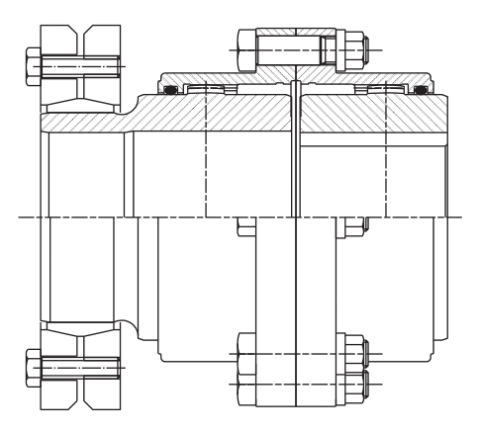

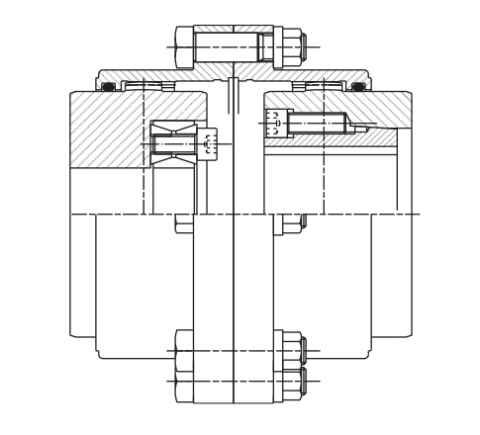

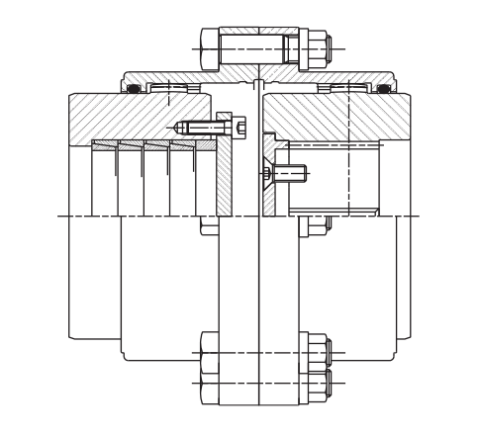

The ESCO gear coupling is a torsionally rigid grease filled coupling consisting of two hubs with external multicrown - and two flanged sleeves with straight internal teeth. The flanged sleeves are bolted together with high strength corrosion protected fitted bolts and nuts. The sleeve is at the opposite side of the flange executed with an endcap (internal for small and screwed for big size couplings) in which the o-ring is located for sealing purposes. The ESCO gear coupling has been designed to transmit the torque between these two flanges through friction avoiding fretting corrosion between these faces.

The teeth of hub and sleeve are continuously in contact with each other and have been designed with the necessary backlash to accommodate angular-, parallel- and axial misalignment within their misalignment capacity. The angular and parallel misalignment capacity is determined by the gear tooth design and is for the standard ESCO gear max. 1.5° degrees (2 x 0.75°) in total. The axial misalignment capacity is limited by the gear teeth length in the sleeve and can be varied (optionally).

Gear couplings are generally made from carbon steel Ck45 (AISI 1040). For higher torque capacities, within the same coupling dimensions, a higher alloy steel like 42CrMo4QT can be used (optionally).

Parallel misalignment can only be accommodated by double engagement type couplings.

The ESCOGEAR F series is robust and reliable. It is ideal for meeting the specific requirements of various rotating equipment machines in all kind of industries, with torque up to 5,040,000 Nm.

The ESCO ADVANTAGE

The ESCOGEAR F – series offers:

- High torque capacity & important angular misalignment allowing the coupling to operate under combined load, speed and misalignment conditions

- An easier coupling selection

- High bore capacity

- Light weight

- The highest manufacturing quality & long coupling life guaranteed

- A Multicrown gear shape

- Perfect homokinetic torque transmission

- Reduced backlash

- Perfect gear top centering

- Zinc coated body fitted flange connection bolts avoiding fretting corrosion in the flange bores

- An excellent protection of component

AVAILABILITIES

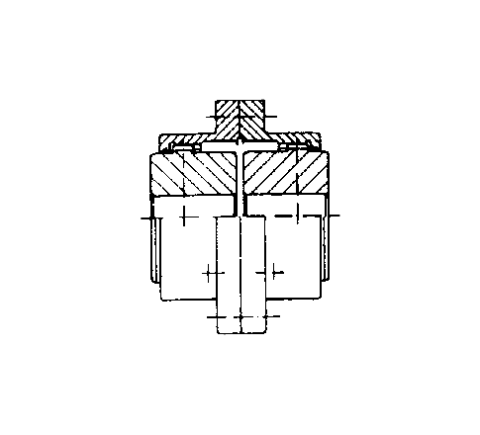

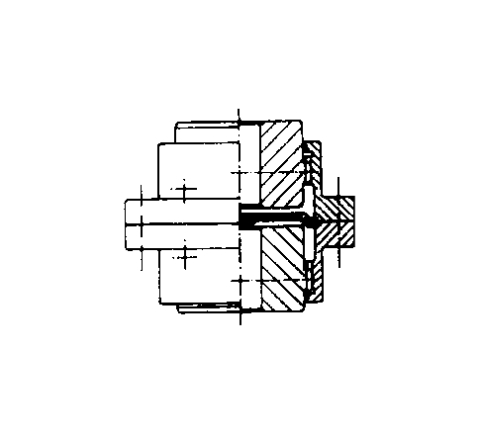

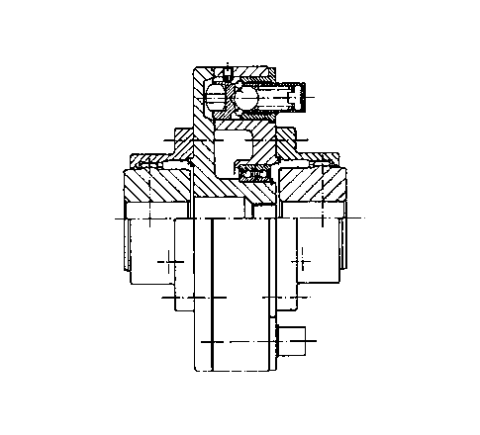

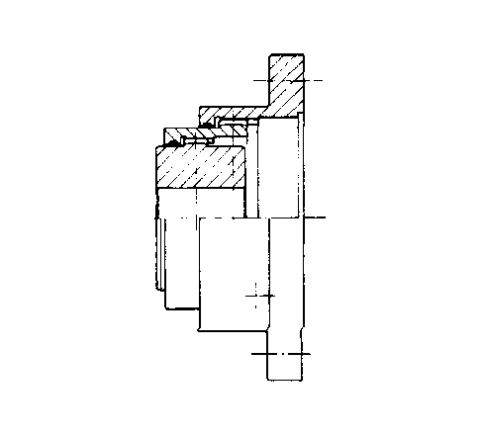

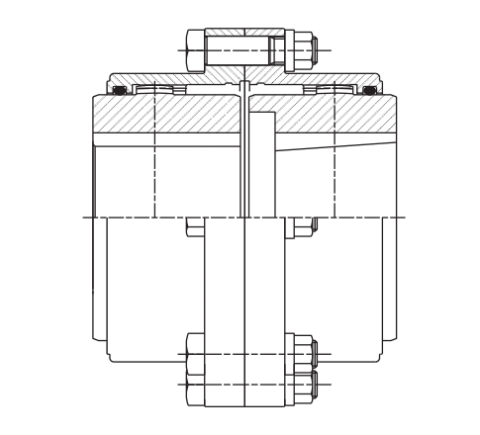

FST

Standard

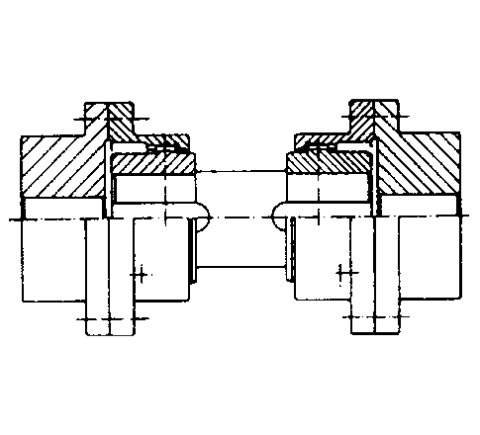

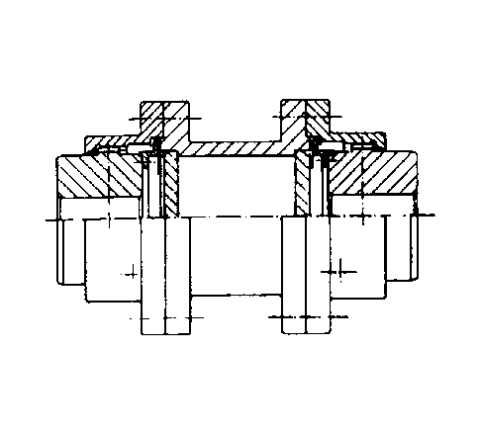

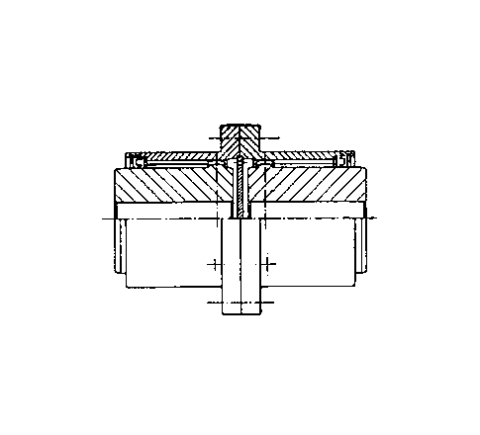

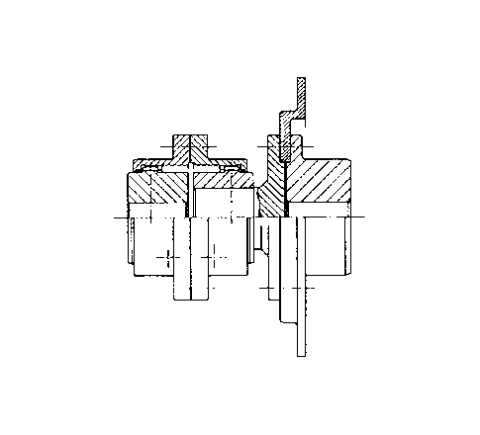

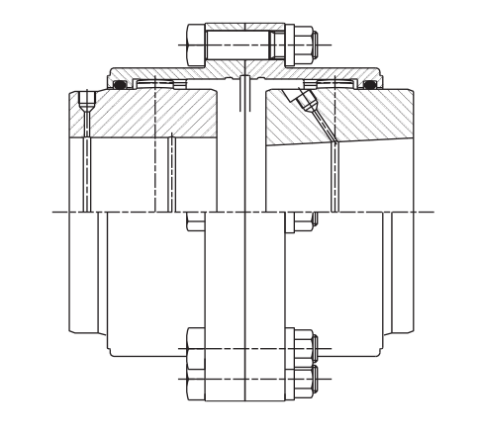

FFS

Drijvende schacht type

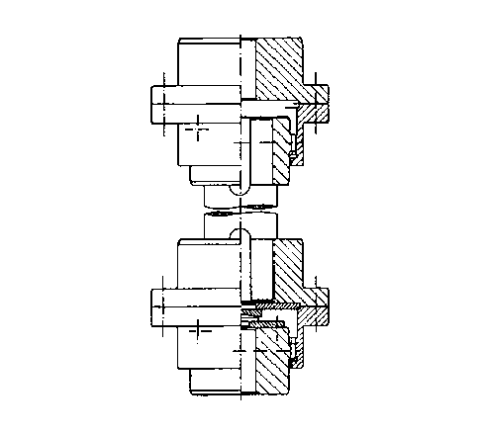

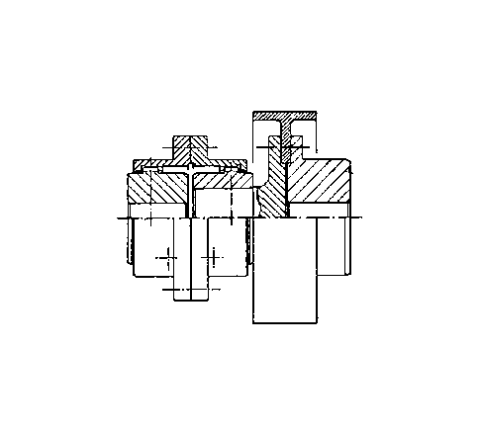

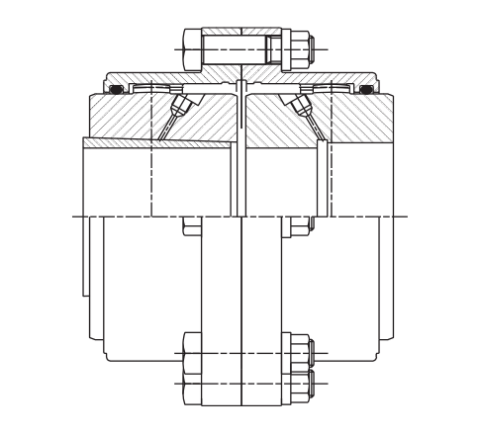

FSE

Spacer execution

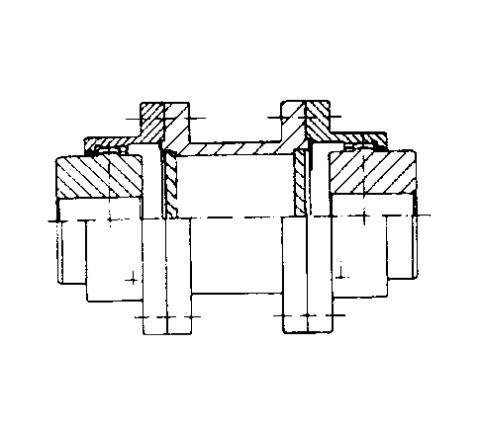

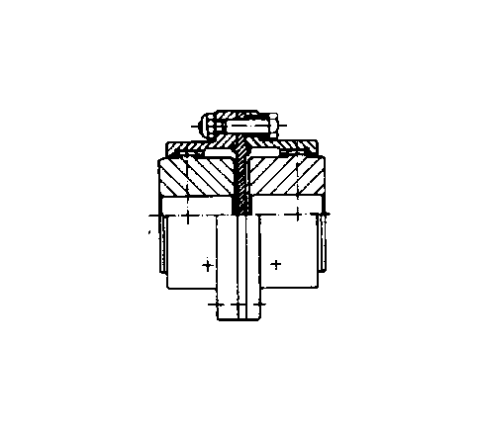

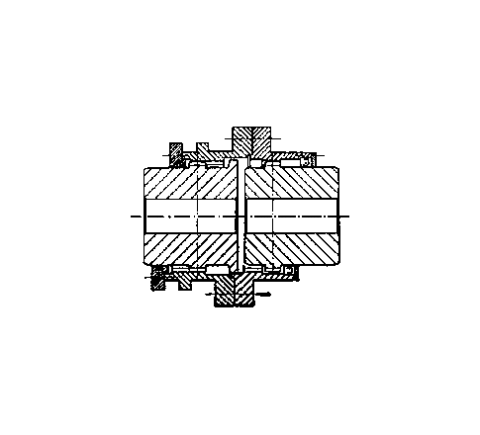

FMM

Mill-motor

FDMM

Double mill-motor

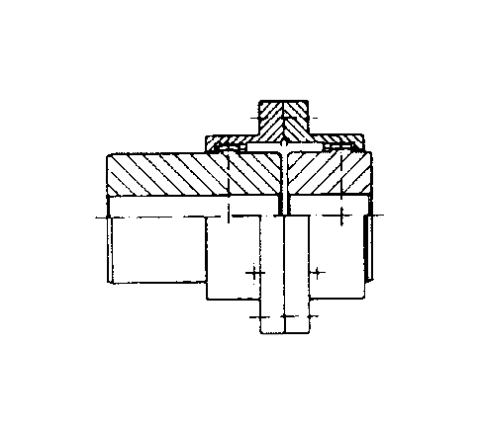

FSH

Sliding hub

FLE

Limited end float

FSP

Shear pin

FSV

Standard vertical

FSLE

Limited end float

FRR

Rigid - rigid

FWD

Winch drum

FET

With Escotorque

Other types available - on request

FDSH

Double sliding-hub

FFSV

Vertical floating-shaft

FIN

Insulated

FFA

To be adapted on on flywheel or flange

FBD

With brake disc

FBP

With brake drum

FCO

Cut-out - shifter type

FSEOS

Shear spacer

SHAFT CONNECTIONS

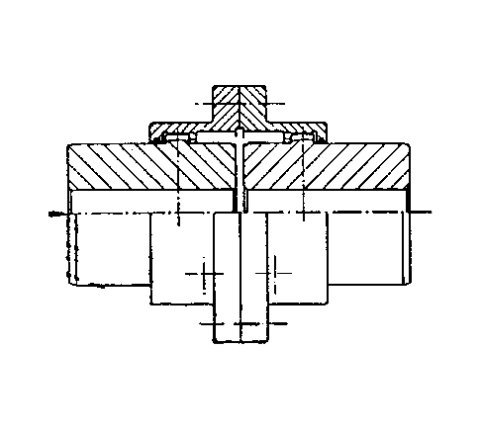

Keyway

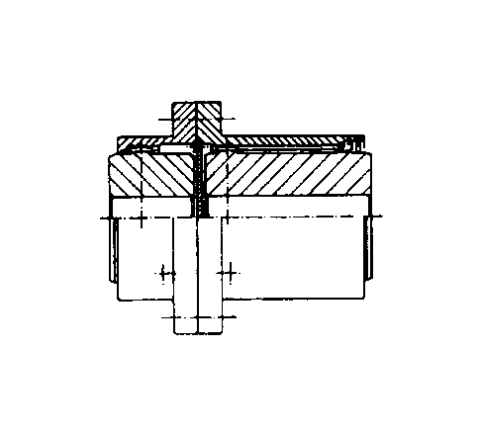

Interference Fit

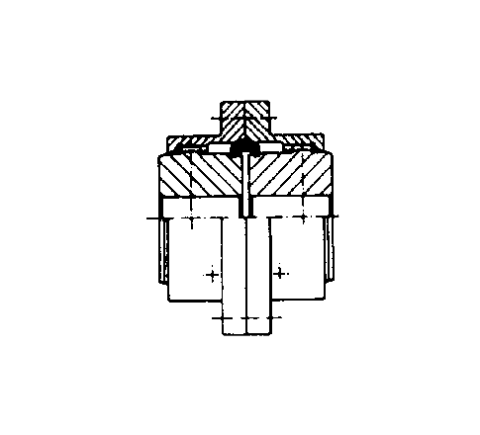

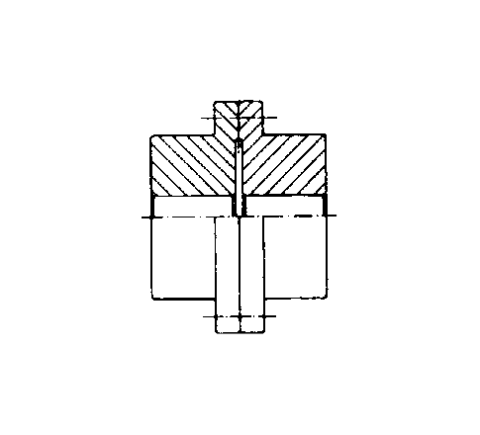

Interference with Intermediate Conical Bushing

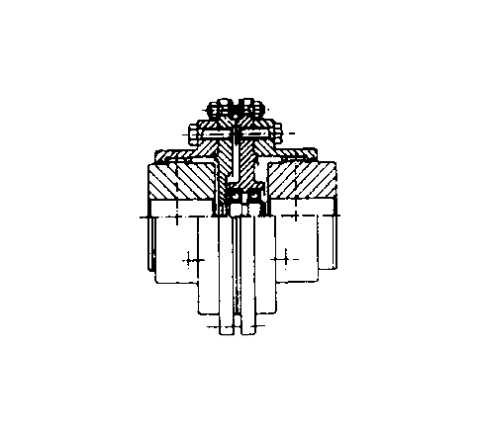

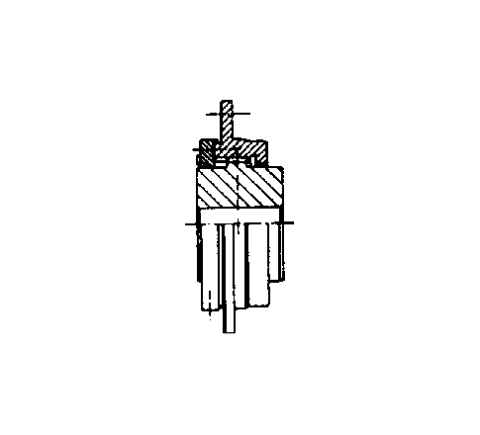

External Clamping

Internal Clamping

Splines